Powder coating equipment SAMES INOCART VT

Powder coating equipment SAMES INOCART VT

520300 €590000 €You save 69700 €In stock.Powder coating equipment SAMES INOCART VT

-

Complete powder package Inocart VT

The Inocart VT is a simple and complete manual solution for applying powder. Partnering the Inogun M spray gun and the Inobox control module enhances the user's experience. It contains a user-friendly interface with advanced ergonomic functions to help maintain the focus on the powder application and the finish quality.

Vibrating table TEC5 Technology Corona charge

- Fast color changes: Under 25 seconds to clean

- Efficient powder transfer: TEC5 technology

- Easy to operate: 2 minutes from training to production

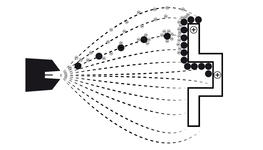

The Inocart VT is perfect for applying an even spray pattern for powders like polyester, epoxy, or acrylic which are supplied in 20 kg (44 lb) boxes. The vibrating table liquidizes the powder and allows the powder pump to move the powder swiftly through the tubing to the manual gun. Powder and energy savings have been incorporated at the heart of the gun's development to reduce work by enhancing productivity and finishing quality of the coating. The TEC5 (Transfer Electronic Control) ensures the self-regulation of the electrostatic charge taking into account the powder flow and distance of the parts in order to optimize the powder transfer and finish quality.

The Inocart VT is easy to clean because of the distinctive Fast-Clean option which also makes it well-balanced and comfortable to operate. The powerful high voltage unit paired with the high voltage control unit Inobox delivers an increased wraparound effect on large parts (D. 500mm / 20 in) and has deep penetration into recessed areas. This reduces the cost of the ownership with a better use rate of powder and reduces the time to spray powder. The Inobox is the main controller behind the Inogun M as it performs the High Voltage and all air controls: current, electrode air clean, injection, and dilution.

The powder hose and the cable are available in two different lengths: 6 meters (19.7 ft) and 12 meters (39.4 ft) to process small or large parts and components. Either can be used as the main tool to perform powder coating or used as additional equipment for pre-touch or touch-up. The desired result will be easily achieved.

POWDER GUN INOGUN M

- Lifetime finish quality: Long life cascade durability and HV performance

- Efficient powder transfer: TEC5 technology

- Balanced and ergonomic design: No repetitive strain damage, less fatigue

The Inogun M is designed to provide the best quality powder application because it is well-balanced, supplied with low voltage cable, powder tube and reactive trigger that requires a gentle touch. The powerful high voltage unit coupled with the high voltage control unit provides a high wraparound effect on large parts (D. 500mm / 20 in) and has deep penetration into recessed areas. This reduces the cost of the equipment with a better powder usage rate and reduces the time to spray the powder.

The Inogun M is controlled by the Inobox which has a clear and easy to use interface. The connected integrated Inocontroller can also be used when it is necessary to integrate an automatic booth. The Inobox and the Inocontroller are the main control centers for manual and automatic applications as it performs high voltage and all air controls: current, electrode cleaning air, injection, and dilution. Dust and energy saving has been implemented at the heart of the gun to reduce waste, and increase productivity and the quality of finishing powder. TEC5 (Transfer Electronic Control) technology provides electrostatic charge self-adjustment, taking into account powder flow and part distance, to optimize powder transfer efficiency and finish quality.

The Inogun M is available in different kits according to the needs of your powder coating process. The Inogun M can be used as a main applicator to perform powder coating and can be mounted on a tank or independent powder supply box on a vibrating table. The Inogun M can be used as a pre-touch or touch-up solution in an automatic booth to obtain the desired coating on the workpiece. The Inogun M is also used for non-destructive testing applications.